目前,海带采收装置多使用吊采法或链采法 [11-12]。而这些收获装置及其支持船存在4个问题:收割过程中解开吊绳,导致收割效率降低[13⇓-15];机械采摘损耗高于人工采摘损耗,如夹破浮球、切断吊绳,或由于脱钩而漏采[16⇓-18];难以根据海带的种类切割出合适长度的海带[13⇓⇓⇓⇓⇓⇓⇓⇓⇓-23];采收装置固化于船,支持船不能用于其他目的[13⇓⇓⇓⇓⇓⇓⇓⇓⇓-23]。免拖伤的海带采收船可以减少采摘损耗,并且可以根据海带的种类进行切梢、去根,但在收割过程中需要逐个解开吊绳,导致效率较低,且收割装置仍固化于船[24]。仿生型海带采收装置通过对人工采收海带动作的模仿,降低采摘损耗,提高了收获效率,但仍固化于船,且无法根据海带的品种类型调整切割长度[25]。因此,海带采收装置及其支持船应从降低采收损耗、提高采收设备利用率、实现支持船多用途化以提高船舶利用率等3个方面进行考虑。具体而言,通过模块化设计,实现船、机的时空分离,利用不同牧场海带成熟期的时间差,或不同品种海带成熟时间差,利用模块化设备即插即用、安装快速的特点和采收速度的高效性,在不同的海洋牧场进行采收,从而提高采收设备的利用率。同时也拓宽了船舶的使用渠道,提高其在非海带采收期的船舶利用率;通过仿生设计,降低采收损耗率,从而有利于推动实现海带采收机械化。

1 设计方法

1.1 模块化设计

所谓模块,就是可以组成系统、具有某种确定功能和接口结构、典型的通用独立单元,具有3个特征:依托接口的分拆性与更换性、功能性、标准性[26]。在本研究中,海带采收装置为采收模块,支持船为支持模块,二者构成海带采收船系统;采收模块具有采收功能,支持模块具有航行、搭载、能源供给功能;采收模块采用标准集装箱为功能舱,将采收设备容纳其中;集装箱底的角件孔与支持船甲板上设置的转锁形成一对接口,借此实现采收模块与支持模块的快速分离与结合。

1.2 仿生性设计

在本方案中,限位及拖曳单元仍采用仿生学设计原理[25],但囿于集装箱空间的限制,将之前拖曳系统中的电液推杆改为传送带系统,同时对限位单元做了优化。

2 采收模块的设计

2.1 载体

集装箱的前、后壁改为铰接,以便前、后壁借助采收装置的运动机构向上掀起。此外,前、后壁上对应设置门,该门与采收装置中的步道对齐。

2.2 引导机构

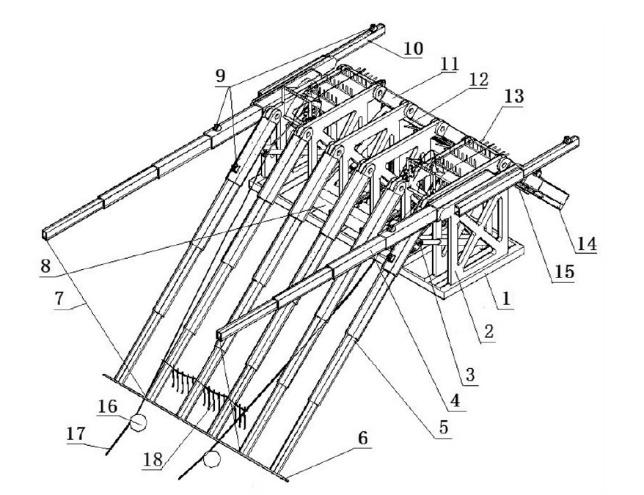

图1为移除集装箱后的采收装置的示意图。前导轨、两前支臂、前横杆和两条拉索一起形成前导轨组,后导轨、两个后支臂和一根带有多个撑杆的后横杆构成后导轨组。前、后导轨及前、后支臂均采用单液压缸插销式伸缩臂。前、后导轨分别在前、后电液推杆的作用下实现俯仰,从而实现3个功能:1)前导轨的俯仰角与其伸缩长度的调整,可以将海带设置于离船合适的距离之上,减少海带受水流作用而粘贴于船壳的几率与面积,从而降低提升海带所需克服的阻力;2)后导轨的俯仰角与其伸缩长度的调整,可以调整海带的去梢位置;3)前、后导轨的俯仰可以实现集装箱前、后舱壁的开合,即导轨将舱壁抬至水平后,由前、后支臂伸出并支撑舱壁,导轨回落至适当角度,实现舱壁开启,以及导轨抬升至水平支撑舱壁后,前、后支臂回缩,后导轨托着舱壁回落,实现舱壁闭合。前水平臂与后水平臂分别用于支撑集装箱的前壁与后壁。相关导轨及前、后支臂上设有滚轮,以减小开启舱壁时的摩擦力。

图1

图1

采收装置

注:1.基座;2.支架;3.电液推杆;4.前水平臂;5.前导轨;6.前横杆;7.拉索;8.滚筒输送机;9.滚轮;10.后水平臂;11.后导轨;12.撑杆;13.限位及拖曳单元;14.后横杆;15.上割刀;16.浮球;17.绠绳;18.装有海带的吊绳、苗绳。

Fig.1

Harvest equipment

Notes: 1.Base;2.Support;3.Electro-hydraulic pusher;4.Horizontal front support arm;5.Front rail;6.Front connecting rod;7.Inhaul cable;8.Roller conveyor;9.Roller;10.Horizontal rear support arm;11.Rear rail;12.Stay rod;13.Limit and towing unit;14.Rear connecting rod;15.Upper cutter;16.Float ball;17.Main rope;18.Crossed rope with kelp.

前支臂与前横杆之间设有拉索,用于对苗绳进行左右限位,苗绳将沿前导轨上升,经支架上沿,运行至后导轨,并沿后导轨下滑。后横杆上设有撑杆,用于与后导轨共同支撑苗绳,以免苗绳因海带的重量而下垂过多,导致去根时切断苗绳。

机架下部设置滚筒输送机,为海带后移提供额外动力。滚筒输送机两侧设置挡板,既防止海带在拖曳过程中滑到相邻的输送机上,也可在被放倒后遮蔽滚筒输送机,构成步道。

2.3 限位及拖曳单元

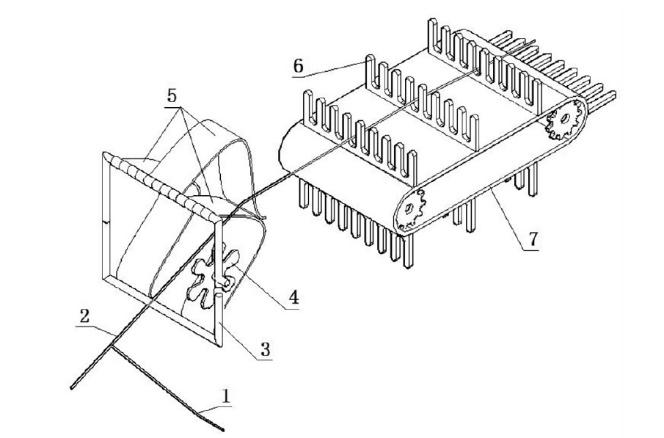

图2

图2

限位及拖曳单元

注:1.苗绳;2.绠绳;3.限位框;4.叶片;5.挡条;6.耙齿组;7.传送链板。

Fig.2

Limit and towing unit

Notes: 1.Crossed rope;2.Main rope;3.Limit frame;4.Rotating blades;5.Limit bar;6.Rake;7.Conveyor chain board.

拖曳机构的主体是传送链。传送链上设有若干耙齿组,每个耙齿组间距略大于浮球的直径,为300 mm;耙齿的间距为50 mm,略大于2倍的绠绳直径,而小于M64六角螺母的对边距,介于其厚度两极值49.1 mm和51.0 mm之间。绠绳上每隔300 mm设置1只未攻丝的M64六角螺母胚料,绠绳上下往复穿过该螺母,使其不会从耙齿间穿过。预系扣浮球和吊绳处的M64六角螺母上焊接1只M32六角螺母胚料,浮球绳和吊绳系扣于该螺母上。

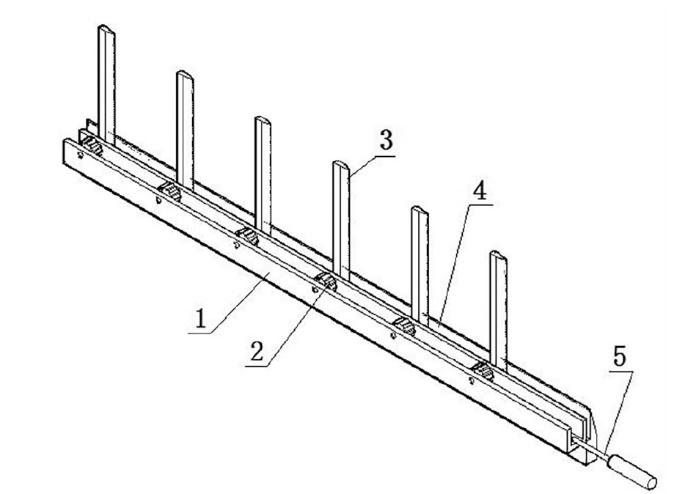

2.4 切割单元

切割单元由上割刀和下割刀构成,上割刀由后横杆支撑,下割刀位于机架后方底部。割刀由滑槽、齿条、固定刀片、连接于齿轮的动刀片和电液推杆构成。电液推杆推动齿条,从而使动刀片转动,与静刀片共同完成剪切,详见图3示意。

图3

图3

割刀

注:1.滑槽;2.齿轮;3.动刀片;4.静刀片;5.电液推杆及齿条。

Fig.3

Cutter

Notes: 1.Chute;2.Gear;3.Movable cutter blade;4.Fixed cutter blade;5.Electro-hydraulic pusher connected the rack.

2.5 工作流程

同绠绳一样设置有M64六角螺母的两根拖索,从后向前穿过限位及拖曳单元,悬垂至船外,而后由船工驾驶舢板拉着拖索,在两拉索范围内,有效连接每根拖索与对应的绠绳。在拖曳单元作用下,绠绳牵拉吊绳,带着携有海带的苗绳沿前导轨上移。当浮球经过限位器时,推开若干挡条,在浮球自身重力及拖曳力作用下迅速、完全地穿过挡条后,挡条恢复对绠绳的限位。当传送链板向后运转时,耙齿组向后推动螺母,从而将绠绳向后拉动。当苗绳被拉到传送链板的下行程面时,苗绳落于后导轨之上,并在其上在海带自身重力作用下,沿后导轨组下滑。待所有的海带苗绳均下滑至底部后,抬升后导轨组至适当位置。若下割刀与上割刀间的海带长度少于所需长度,则继续抬升。若抬升至最高处仍不够,则可启动滚筒输送机,使其向后运输一段海带,以满足长度要求。而后启动下割刀,切去海带梢,然后再启动上割刀,切去海带根部,如图4所示。

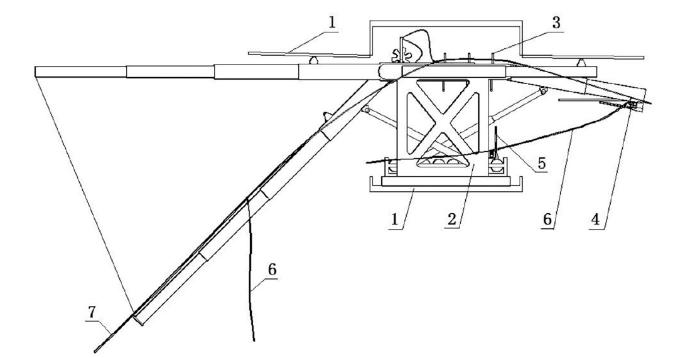

图4

图4

采收示意图

注:1.集装箱;2.机架;3.限位及拖曳单元;4.上割刀;5.下割刀;6.海带;7.绠绳。

Fig.4

Sketch map of harvest modular

Notes: 1.Container;2.Body of the harvest equipment;3.Limit and towing unit;4.Upper cutter;5.Lower cutter;6.Kelp;7.Main rope.

3 支持模块的设计

3.1 船型方案

由于海带的采收期主要集中于每年的4—8月间,约占全年时间的1/3,因此支持船需在余下的时间中从事其他作业,以提高利用率。海洋牧场除养殖海带外,还养殖鱼类或贝类,对放置和维护人工礁、释放鱼苗、捕捞渔获、监测海洋环境、旅游观光和进行科学教育有一定的需求[30⇓-32]。因此,支持船应具有以下特点:1)具有较大的甲板作业面,以便于网具收放,并配备吊机以利于网箱换网、吊放吸鱼泵管道和人工鱼礁等;2)具有良好的直航性和操纵性,以便在筏架区或网箱区的狭窄水道中顺利航行、作业;3)能够搭载采收模块。依据上述3点,采用小型双体船为佳——两片体宽度及其间距和双桨的配置既保证了甲板的宽大和船舶的直航性、两桨差动,也为船舶提供了良好的操纵性,而甲板的宽大也便于搭载采收模块、网具、人工鱼礁等。对于兼顾海区环境监测、观光垂钓、科普教育的支持船,由于其所服务的对象多为易于晕船、短期在船的人员,因此适宜采用耐波性好的特殊双体船——以小水线面双体船为佳[33]。由于文献[33]对此船型已有论述,本文仅论述采用常规双体船的方案,该船型多用于搭载海带采收模块、放置和维护人工礁、释放鱼苗、捕捞渔获。

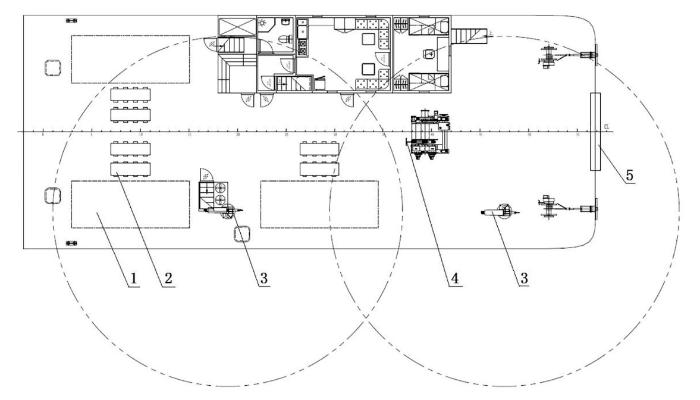

图5为小型双体船方案的主甲板图。该方案中,船舶总长为29.5 m,型宽为12.0 m,型深为3.3 m,吃水2.1 m,设计排水量为203 t。每个片体内设置1台122 kW的主机,设计航速为10节。船舷右侧设置2部型号为M125.20A3的折臂吊车,吊机最大额定吊力为2.45 t,额定起重力矩为114.9 kNm,最大吊臂范围10.1 m;中部设置1部起网机;首部设置1个滚筒。船上设有3处与集装箱配套、用以固定集装箱的转锁,视筏架布局,选择对称或单侧设置采收模块。采收模块处栏杆设置为可倒栏杆,以适应采收装置前导轨的俯仰。

图5

图5

支持船甲板平面

注:1.采收模块;2.自行小车;3.吊机;4.起网机;5.滚筒。

Fig.5

Deck plan of supporting ship

Notes: 1.Harvest modular;2.Auto-vehicle;3.Knuckle boom crane;4.Winch;5.Rotary drum.

3.2 使用方法

当支持船用于采收海带时,首先将采收模块底部角件孔与支持船甲板上的转锁对接锁定,然后将采收模块的电气接口与船上供电接口连接,之后便可按前述操作方法采收海带。每一采收装置与2部无人驾驶小车配合作业,车内设网具,车长略大于苗绳长度。采收过程:海带先去梢,而后将其端部放入外侧小车网中,再切去根部,之后滑入网中;滚筒输送机将海带梢输入内侧小车网内;小车驶入吊机作业区,由船载吊机将网具及其内的海带吊运至位于支持船船首或舷侧的转运船上,而小车自动返回原作业区,等待下一次作业;船舶在筏架组间垂直于绠绳的纵向水道中行进、采收,直至驶至该水道尽头,而后掉头驶入另一筏架组间水平水道进行作业。自始至终,船舶不进入两绠绳之间采收,也不进入平行于绠绳的横向水道进行作业。

4 讨论

4.1 采收效率

以山东省荣成市的海带养殖模式为例,苗绳按1.5 m间距平行设置于2根长度为75 m的绠绳之上,一般设50根苗绳,每根苗绳上存有海带100 kg,在拖曳速度为0.1 m/s的情况下[25],拖曳时间为12.5 min。电液推杆的工制一般为工作10 min、休息10 min,因此完成一个浮筏作业的采收时间可近似为25 min,每个模块可收获海带5 000 kg 。在理想状态下,船舶可以在休息期间进行移位、挂绳、转运等作业,因此在每天6 h的拖曳时段中,每个采收模块可作业14次,收获海带70 000 kg。

4.2 船型布置

采收模块设置于两侧,用于同时采收左右2个筏架上的海带;置于同侧,则用于采收同一筏架上不同列浮筏上的海带。此外,在浮筏间水道及经济条件允许的情况下,也可以采用较长的船舶,两侧对称设置多个模块,可大幅提高每天的采收量,并可兼顾储运海带。

4.3 导轨防腐

本文中所用的导轨为单液压缸插销式伸缩臂,其内部伸缩、锁定机构较为精密,因此入水的前导轨的防腐是一个值得研究的问题。若内部锁定机构可采用工程塑料制作,或用工程塑料包覆,则可以提高设备的防腐能力,这需要进一步研究。

4.4 作业模式

目前长青海洋科技股份有限公司的采收作业模式为人工采收,1 000人、1 000艘舢板每天共采摘6×106 kg。按此采摘量,在理想状态下,共需43艘母船搭载86只采收模块进行采收,以及150余舢板进行转运。而一般海洋牧场没有如此多的母船,因此,有必要考虑邻近海洋牧场的联合作业。但联合作业需考虑到各海洋牧场的定位,因而还需要进一步摸索、探讨。或者成立专业海带收割队伍,通过陆路运载采收模块至相关海域,并租用船只,搭载模块进行采收,这不仅可使海洋牧场方及收割队减少大量设备投资及维护费用,而且可让当地船舶拥有者通过租船,提高船舶的利用率并获利。

4.5 搭载其他海带采收设备

本研究设计的支持船也可用于搭载其他海带采收设备,只需在该采收设备的适当位置处加装集装箱底部的角件孔。本船也可以不采用小车,而改为传送带,由传送带将海带输送至停泊于支持船首尾端的转运船上。

4.6 未来可能的拓展

未来可能加装测量系统,自动测量海带所需长度,从而据此将水流速度、拖曳速度、后导轨俯仰角度、滚筒输送机运转速度及启停时间、割刀切割时间统一协调起来,由电脑控制,进一步减轻工作人员的劳动强度。

5 结论

模块化海带采收装置基于模块化原理和仿生原理,以机械设备模仿人工采收,在降低采摘损耗的同时,大幅提高劳动效率,降低劳动强度;将采收装置与船舶分离,有利于提高船舶利用率。模块化采收可作为海带采收、乃至可拓展为贝类采收的一个有前途的发展方向,有可能推动海洋牧场发展出新的管理模式——类似目前陆地农业中的农机专业化运作形式。模块化海带采收装置将有助于推动海带成为蓝碳的重要制造者,为控制碳排放作出贡献。目前该装置与支持船仍处于研究阶段,各单元的合理性仍需进一步优化。同时,采收船各设计参数也需要进一步研究,以期满足未来生产的需要。

参考文献

Installing kelp forests/seaweed beds for mitigation and adaptation against global warming: Korean project overview

[J].Chung, I. K., Oak, J. H., Lee, J. A., Shin, J. A., Kim, J. G., and Park, K.-S. 2013. Installing kelp forests/seaweed beds for mitigation and adaptation against global warming: Korean Project Overview. – ICES Journal of Marine Science, 70: 1038–1044. Seaweed beds can serve as a significant carbon dioxide (CO2) sink while also satisfying global needs for food, fodder, fuel, and pharmaceutical products. The goal of our Korean Project has been to develop new baseline and monitoring methodologies for mitigation and adaptation within the context of climate change. Using innovative research approaches, we have established the Coastal CO2 Removal Belt (CCRB), which comprises both natural and man-made plant communities in the coastal region of southern Korea. Implemented on various spatial–temporal scales, this scheme promotes the removal of CO2 via marine forests. For example, when populated with the perennial brown alga Ecklonia, a pilot CCRB farm can draw down ∼10 t of CO2 per ha per year. This success is manifested by an increment in biomass accumulations and a decrease in the amount of dissolved inorganic carbon in the water column.

Production,respiration and exudation of dissolved organic matter by the kelp Laminaria hyperborea along the west coast of Norway

[J].Changes in O2 concentration were measured during in situ incubation of whole, young Laminaria hyperborea and used to evaluate primary production and respiration over a 3-y period (1995–1998). The exudation of dissolved organic carbon (DOC) during incubation was also measured. Total carbohydrates and polyphenols in the exudates and the regional seawater were determined and fractionated into low molecular weight (LMW) and high molecular weight (HMW) species. Net production rates varied significantly, being highest during the growth phase (March), while respiration rates did not vary significantly. The exudation rates correlated with the plant strategy of growth and production in which high requirements for growth led to a lower proportion of fixed carbon being exuded. More fixed carbon was exuded during the non-growth phase. The annual exudation of DOC is estimated to be ∼26% of fixed carbon and amounts to ∼1·29 kgC m−2 y−1. The annual amount of carbon retained by the kelp (the difference between fixed and exuded carbon), assumed to contribute to growth, corresponds to a biomass increase of 3·0 kgC m−2 y−1, a value similar to those reported using direct measurements of biomass increase in the region. Carbohydrate concentrations in the exudates were lower during March than in other months, in accordance with the plant growth strategy. Phenols, on the other hand, which are assumed to function as predator deterrent, showed no significant variations in the exudate. The fraction is dominated by carbohydrates while phenols occurred mainly in the LMW fractions.

Substantial role of macroalgae in marine carbon sequestration

[J].Vegetated coastal habitats have been identified as important carbon sinks. In contrast to angiosperm-based habitats such as seagrass meadows, salt marshes and mangroves, marine macroalgae have largely been excluded from discussions of marine carbon sinks. Macroalgae are the dominant primary producers in the coastal zone, but they typically do not grow in habitats that are considered to accumulate large stocks of organic carbon. However, the presence of macroalgal carbon in the deep sea and sediments, where it is effectively sequestered from the atmosphere, has been reported. A synthesis of these data suggests that macroalgae could represent an important source of the carbon sequestered in marine sediments and the deep ocean. We propose two main modes for the transport of macroalgae to the deep ocean and sediments: macroalgal material drifting through submarine canyons, and the sinking of negatively buoyant macroalgal detritus. A rough estimate suggests that macroalgae could sequester about 173 TgC yr(-1) (with a range of 61-268 TgC yr(-1)) globally. About 90% of this sequestration occurs through export to the deep sea, and the rest through burial in coastal sediments. This estimate exceeds that for carbon sequestered in angiosperm-based coastal habitats.

筏式养殖海带收获装置的发展现状

[J].我国是世界上最大的海带养殖国。目前,养殖海带的采收主要依靠人工完成,劳动强度大,效率低,成为制约海带产业发展的瓶颈因素之一。随着劳动力成本攀升,从事艰苦作业劳动力短缺,迫切需要发展海带机械化收获技术。本文主要针对筏式养殖海带的机械化收获装置的研发现状进行综述与分析。在介绍筏式养殖海带模式特点及手工收获海带过程的基础上,对各种海带收获装置的特点进行了介绍,归纳了海带收获装置的行进、苗绳捕获及分离、传输和加工等核心模块及其功能特征,分析了海带养殖形式对海带收获装置的结构和设计的影响,提出需要综合考虑海带形态特点、生长环境和养殖模式的特殊性来研发适合我国国情的海带收获装置,探讨了海带收获装置开发中需要注意的问题。

Creating a sustainable commercial harvest of Laminaria hyperborean,in Norway

[J].

一种新型的海带收割装置:201510152393.2

[P/OL].(2019-04-09)[2023-01-30]. https://kns.cnki.net/kcms/detail/detail.aspx?dbcode=SCPD&dbname=SCPD201901&filename=CN104756667B&uniplatform=NZKPT&v=TSlJZhvAR0BtDaDq4he3khL_yFz0CH5NqQhzpOqlTur3YXL8_eRVz5tc1eBmcdrO.

海带收割机:201420666807.4

[P/OL].(2015-03-25)[2023-01-30]. https://kns.cnki.net/kcms/detail/detail.aspx?dbcode=SCPD&dbname=SCPD2015&filename=CN204217474U&uniplatform=NZKPT&v=BTSL6fPgOZEi2mUouIe9UyvX NTv8JGee0UW2UNkIl04lTh9KcJFHuIuFTSqElpNI.

海带收获船:201310399215.0

[P/OL].(2015-07-22)[2023-01-30]. https://kns.cnki.net/kcms/detail/detail.aspx?dbcode=SCPD&dbname=SCPD202201&filename=CN103477796B&uniplatform=NZKPT&v=bemEP9X5yVcnXT_BBo0jCC4ZA9-GexPmciq1GG4fb-sknmnka1KKVOwZfLFcpb01.

一种机械化海带收割船和收割方法:201910952142.0

[P/OL].(2022-03-29) [2023-01-30]. https://kns.cnki.net/kcms/detail/detail.aspx?dbcode=SCP.D&dbname=SCPD202202&filename=CN110622688B&uniplatform=NZKPT&v=XBdgmYJ5buhwCH1XSVgshr5Zp4_yCJysElBCMqw6w_UzlNZrmavXClWtazDi5c6k.

一种新型海带收割机:201621070300.8

[P/OL].(2017-04-26)[2023-01-30]. https://kns.cnki.net/kcms/detail/detail.aspx?dbcode=SCPD&dbname=SCPD2017&filename=CN206118426U&uniplatform=NZKPT&v=Tu2tm8BgD1gmJ1Hwmv1eYweeZ_6WitjiS8eABXCIoV5cBdOADMwOm24QC0yxgwSn.

半潜式海带收割船:201310720554.4

[P/OL].(2016-03-06)[2023-01-30]. https://kns.cnki.net/kcms/detail/detail.aspx?dbcode=SCPD&dbname=SCPD202201&filename=CN103718735B&uniplatform=NZKPT&v=RiTS IUmVefYl3xjahCR8JbRNVZhEDd296847jtdA23xH3aklQS9WzIKzAqHG1VW.

一种浮式海带收割机:201611090308.5

[P/OL].(2018-08-17)[2023-01-30]. https://kns.cnki.net/kcms/detail/detail.aspx?dbcode=SCPD&dbname=SCPD202202&filename=CN106576585B&uniplatform=NZKPT&v=13zr_nMxeAgmgRCY5lKjWZkXH6zYidFGcb6TXb0F9hFsAYkbVe4RzJByrGus-yIL.

一种具有降低浮球被夹持结构的自动化海带收割平台:202010519268.1

[P/OL].(2021.06.15)[2023-01-30].https://kns.cnki.net/kcms/detail/detail.aspx?dbcode=SCPD&dbname=SCPD202102&filename=CN111527870B&uniplatform=NZKPT&v=S-3FfU47S21ZLDSTzq7JYhkVVPITxzd8RQUEZYEnCI3Nel1fDJLAw3JXBa7a7_sl.

一种新型海带收获船:201720631599.8

[P/OL].(2018-01-30)[2023-01-30]. https://kns.cnki.net/kcms/detail/detail.aspx?dbcode=SCPD&dbname=SCPD2018&filename=CN206939006U&uniplatform=NZKPT&v=5M5RxMdgc_KT0cVexdBpELOsYNVsa9Tp0ZjihgmnSKO2qborlczt-rTu6HC0fjQ0.

一种新型吊装式海带收获机:201820317962.3

[P/OL].(2018-10-09)[2023-01-30]. https://kns.cnki.net/kcms/detail/detail.aspx?dbcode=SCPD&dbname=SCPD2018&filename=CN207940023U&uniplatform=NZKPT&v=LFj2sa9NYu2DbeDV0nG0vzAG06hBqGae6XW7C216HJBgBvZ70hEkNcP8-sjlItqN.

一种免拖伤的海带采收船:201821481141.X

[P/OL].(2019-07-16)[2023-01-30]. https://kns.cnki.net/kcms/detail/detail.aspx?dbcode=SCPD&dbname=SCPD201902&filename=CN209105664U&uniplatform=NZKPT&v=z5biKRNxFDK9AmGQFFZ-rTFmi2rohkArOqy2Y2HAA7ib7C4ZEeB9aQOjCM8aKvEj.

仿生型海带采收装置的研究

[J].现有的海带采收船多采用带收法或吊收法,此二法多用于采收野生海带或浮筏垂养海带。带收法用于浮筏平养海带,但会导致割绳、损坏浮球等问题。为解决上述问题,在对人工采收浮筏平养海带动作进行分析的基础上,依据功能仿生原理,设计限位器:模仿握绳之手对绠绳的限位和运动阻断的功能,以电液推杆及夹具模仿人工伸、曲臂,完成拉绳动作,并配以绳索连接器,从而使得在采收完一筏海带之前,不必解开或切割吊绳,也不必解开浮球,从而保证采收作业的连续性。同时,配以割刀,从而能在采收过程中,对海带进行去梢、去根,并可利用传送带分别传送海带主体与海带梢到其他船只,不仅有利于提高工作效率,而且可以减轻劳动强度。